Adhesive Lined Dual Wall Heat Shrink Tubing Co-extrusion Line is a type of production line that can produce heat shrink tubing with an inner layer of adhesive and an outer layer of polyolefin. The co-extrusion process involves melting and extruding two different materials through a single die, forming a tube with a dual wall structure.

Dual wall heat shrink tubing extrusion line is a production line that manufactures dual wall heat shrink tubing by using a co-extrusion process.

The extrusion line consists of several components, such as;

A raw material feeding system that supplies the polyolefin and adhesive materials to the extruders.

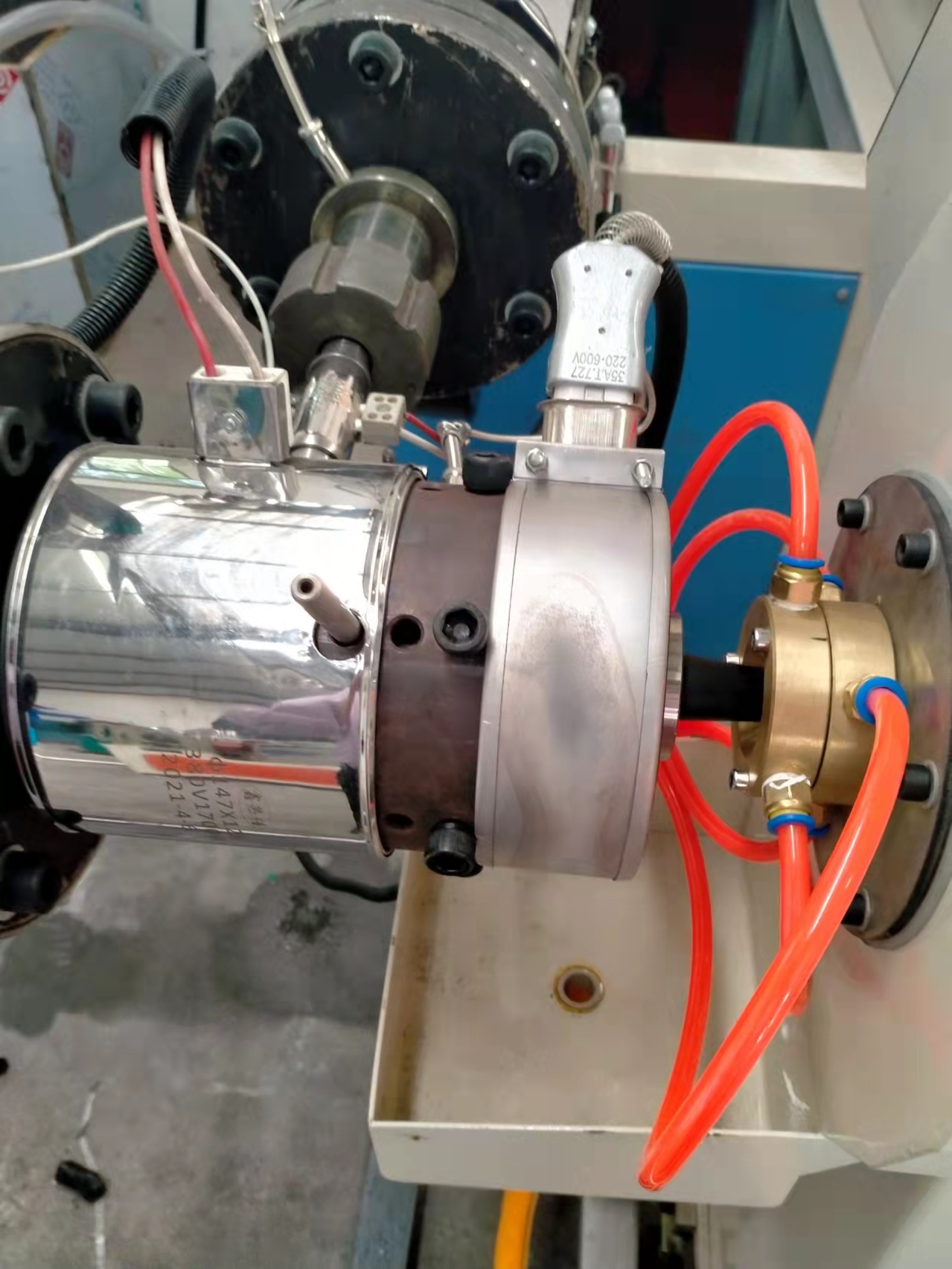

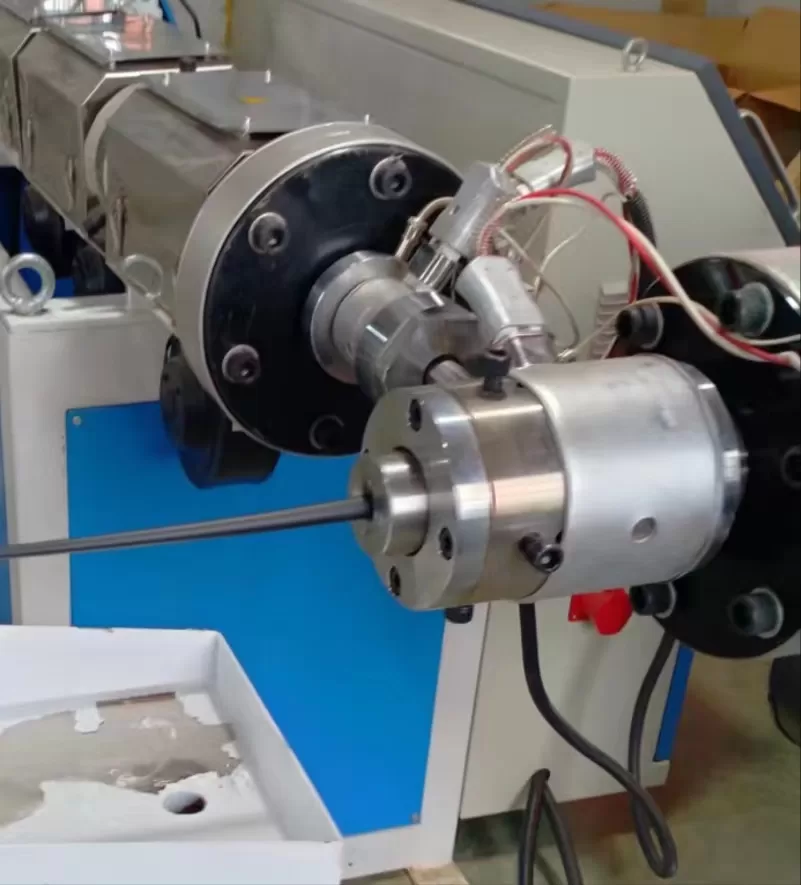

Two single screw extruders that melt and convey the materials to the die head. One extruder is for the outer layer and the other is for the inner layer.

A co-extrusion die head that combines the two materials and forms the tubing shape. The die head also controls the thickness and ratio of each layer.

A vacuum sizing tank that cools and calibrates the tubing diameter and roundness.

Adhesive Lined Dual Wall Heat Shrink Tubing Co-extrusion Line

1. Co-extrusion Heat Shrink Tubing Extruder Models:

SJ-45 tubing extruder+ SJ-30 adhesive extruder

SJ-50 tubing extruder+ SJ-45 adhesive extruder

SJ-55 tubing extruder+ SJ-45 adhesive extruder

SJ-65 tubing extruder+ SJ-55 adhesive extruder

2. Co-extrusion Heat Shrink Tubing Die:

Within a certain range, dies of different specifications can be replaced to produce products of different specifications.

3. Two types Cooling and Shaping Water Tanks:

Immersion cooling and shaping water tank and vacuum cooling and shaping water tank.

Immersion cooling and shaping water tank is mainly used for extrusion cooling and shaping of small-size heat shrink tubing, Vacuum cooling and shaping tank is mainly used for extrusion cooling and shaping large-size heat-shrink tubing.

4. Two types Tractors :

Twin-roll tractor (composed of two pairs of rubber rollers) is mainly used for the extrusion and traction of small-size heat shrink tubing,

Crawler tractor (two traction tracks composed of a rubber belt or rubber block) is mainly used for the extrusion and traction of large-size heat shrink tubing

5. Winding Machine:

Large-diameter winding machines are used to prepare for the next step (preparation for electron accelerator irradiation) Small-size heat shrink tubing needs to be plied and winded to the winding plate together and then the branching machine separates the tubing after irradiation.

6. The extrusion production line is equipped with an automatic vacuum feeding machine with a drying hopper, The models are: 25kG, 50kG, 75kG, 100kG

Model Selection; Adhesive Lined Dual Wall Heat Shrink Tubing Co-extrusion Line

No.1 main equipment components:

Co-extruder—Co-extrusion Die–Cooling&Shaping Water Tank-Roll Tractor-Plying&Winding Machine- Branching Machine

Model; SJ-45+SJ-30 for Φ2.4-Φ7.9mm

Model; SJ-50+SJ-45 for Φ6.4-Φ19.1mm

No.2 main equipment components:

Co-extruder—Co-extrusion Die–Cooling&Shaping Water Tank-Belt tractor-Winding Machine

Model; SJ-50+SJ-45 for Φ25.4-Φ50mm

No.3 main equipment components:

Co-extruder—Co-extrusion Die–Cooling&Shaping Water Tank-Shaping Die-Belt Tractor–Winding Machine

Model; SJ-65+SJ-55 for Φ50-Φ100mm

(Adhesive Lined Semi-Rigid Heat Shrink Tubing)

Model; SJ-90+SJ-65 for Φ100-Φ230mm

(Adhesive Lined Semi-Rigid Heat Shrink Tubing)

The type Co-Extruder also produces adhesive-lined medium wall tubing and adhesive-lined heavy wall tubing